TUBULAR AIR HEATERS

Brand: Alfa Heaters, Product Code: standard, Availability: In Stock

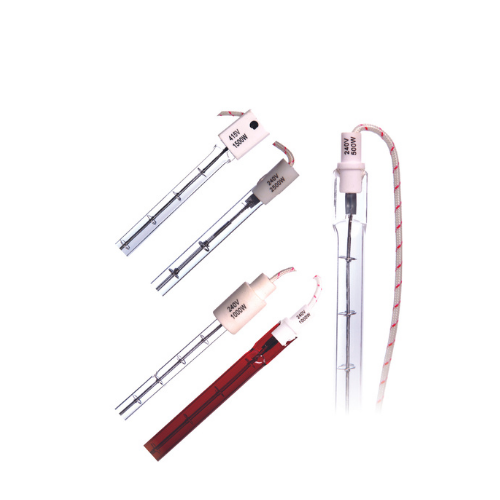

Tubular Heating Elements

Tubular heating elements are highly versatile and efficient components designed for various industrial heating applications. Made from Nickel-Chrome wire, which is helically wound, the coil is encased in a SS 304 sheath. The space between the coil and the tube is filled with Magnesium Oxide (MgO), which enhances thermal conductivity, dielectric strength, and extends the heater’s lifespan.

Finned Tubular Heaters

Finned heaters are designed for fast air heating, using fins (SS or MS) mounted onto the tubular elements to increase surface area and enhance heat dissipation. They’re widely used in duct heaters and air-handling systems.

Design & Construction

Coil: The Nickel-Chrome wire is wound helically to produce high heat output.

Sheath: SS 304 stainless steel is used for durability and corrosion resistance in high-temperature environments.

Insulation: Magnesium Oxide (MgO), with a specifically selected grain size, ensures efficient heat transfer and insulation.

Compression: The tube is compressed via a swaging machine, which secures the coil in the center of the tube, ensuring uniform heat distribution.

Terminals: Stainless steel screw-type terminals securely connect the coil to the power supply, with one end of the coil welded to the screw’s inner end.

Applications

These heating elements are used in a range of applications including:

Air heating (HVAC systems, blowers)

Forming machines

Immersion heating (liquids, oils, solvents)

Hot runner moulds

Ovens, dryers, and dishwashers

Sterilizing equipment

Ordering Information

When ordering, specify:

Sheath Material: SS 304, SS 316 or Incoloy

Diameter: Standard sizes include 6 mm, 8 mm, or 11 mm and 16 mm

Wattage & Voltage

Bend Type & Dimensions

Flange Dimensions

Design Features

Resistance Tolerance: +10%, -5%

Wattage Tolerance: +5%, -10%

Max Sheath Temp: SS 304: 650°C, Incoloy: 875°C

Max Voltage: 480 V AC, Max Current: 40 Amps

Connect with us

Frequently Asked Questions

A tubular heating element is a type of electrical heating component that consists of a Nickel-Chrome wire coil encased in a stainless steel sheath. It is used to generate heat for various industrial applications such as air heating, immersion heating, and more.

Tubular heating elements are primarily made from Nickel-Chrome wire for the coil and SS 304 stainless steel for the sheath. The space between the coil and sheath is filled with Magnesium Oxide (MgO) for better thermal conductivity and insulation.

These elements are used in a variety of applications, including air heating, forming machines, immersion heating, hot runner moulds, ovens and dryers, dishwashers, and sterilizing equipment.

The maximum sheath temperature depends on the material:

SS 304: 650°C

Incoloy: 875°C

The maximum voltage is 480 V AC, and the maximum current is 40 Amps.

Yes, tubular heating elements can be customized for specific applications by adjusting parameters such as diameter, wattage, voltage, bend formation, flange dimensions, and more.

With proper maintenance and usage within specified limits, tubular heating elements can last for many years. The use of Magnesium Oxide insulation enhances their longevity by reducing wear and tear.

Yes, tubular heating elements are highly efficient due to their ability to generate heat quickly and maintain consistent temperatures, minimizing energy wastage.

These elements are designed with stainless steel screw-type terminals for secure electrical connections. The Magnesium Oxide insulation ensures electrical safety and thermal performance while protecting against electrical faults.

To choose the right tubular heating element, consider factors such as application type, temperature range, power requirements, and customization needs like bend formation and flange dimensions. Consult with a supplier to ensure compatibility with your system.