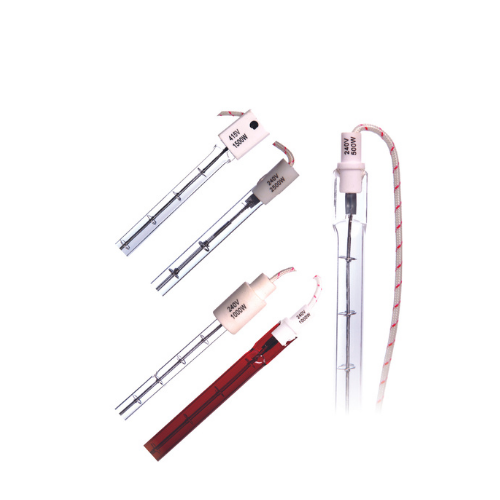

Ceramic Band Heaters by Alfa Heaters and Controllers

At Alfa Heaters and Controllers, we take pride in being specialized ceramic band heaters manufacturers, delivering solutions designed to meet the growing demand for energy efficiency and streamlined operations. Our ceramic insulated Band Heaters are crafted to provide exceptional performance by efficiently transmitting heat through conduction and radiation, making them a reliable choice for various heating applications.

Innovative Design and Superior Construction

Our ceramic band heaters feature a unique construction that enhances durability and performance:

- The heating element comprises a helically wound resistance coil made from high-quality Nickel-Chrome wire. This coil is carefully threaded through precision-engineered ceramic bricks, ensuring even stretching and forming a flexible ceramic heating mat.

- To prevent heat loss, the mat is sheathed in insulating fiber wool, which effectively minimizes outer-side heat emissions.

- A robust serrated cylindrical stainless-steel housing encloses the heating mat and insulation wool, offering additional protection and durability.

This thoughtful design ensures that the heaters are flexible, easy to install, and built to withstand challenging industrial environments.

Unmatched Performance and Versatility

Engineered for peak efficiency, our ceramic insulated Band Heaters operate with a maximum watt density of up to 7 watts per square centimeter and can endure temperatures as high as 760°C. For added versatility, these heaters are available with optional blowers. In blower configurations, insulation materials are removed, and the blower is mounted externally to suit specific customer requirements.

To further customize the experience, the heaters come with multiple termination options, allowing clients to select the best fit for their applications.

Why Choose Alfa Heaters and Controllers?

- Energy Efficiency: Designed to conserve energy while optimizing operational efficiency.

- Customization: Tailored to meet the unique needs of our customers, ensuring compatibility with varied applications.

- Ease of Installation: Flexible structure that allows quick and hassle-free installation.

Whether you’re looking for robust heating solutions or precision-engineered products, Alfa Heaters stands out as one of the leading ceramic band heaters manufacturers. Our ceramic band heaters are crafted with attention to detail, ensuring both superior performance and reliability in every product.

Trust Alfa Heaters and Controllers for innovative solutions that meet your energy-saving and operational needs. Reach out today to learn how our advanced heaters can contribute to your success.

Ceramic Band Heaters – Design Features, Applications, and Specifications

Design Features

Alfa Heaters’ ceramic band heaters are engineered to optimize energy efficiency and performance. These features guarantee reliability, longer service life, and ease of installation:

- Energy-Saving Design: Minimizes power consumption for cost-efficient operation.

- Minimal Heat Loss: Built-in thermal insulation reduces unnecessary heat dissipation.

- Uniform Temperature: Ensures consistent heat distribution for precision.

- Flexibility and Easy Installation: Designed for effortless setup in various applications.

- Extended Heater Life: Durable construction enhances longevity, providing value and reliability.

Applications

The versatility of our ceramic band heaters makes them ideal for numerous industries. These are some of the primary applications:

- Heating barrels in plastic injection molding and extrusion machines.

- Wire and cable production.

- Die and die holder heating for plastics and blow molding machinery.

- Heat treating for pipes and cylindrical surfaces.

- Plastic and rubber processing applications such as blow molding, film extrusion, and heating pipes.

- Specialized heating for extrusion barrels and dies.

Ordering Information

To ensure you receive the right ceramic band heater for your needs, consider the following specifications when placing your order:

- Required wattage and voltage.

- Operating phase (1 Phase or 3 Phase).

- Inside diameter and width to fit your equipment.

- Preferred lead wire type and length.

- Desired thermocouple location.

- Heater construction (one-piece or two-piece).

- Lead wire insulation options (Fiber Glass Sleeving, Braided Metal Sleeve, Armor Type).

- Clamping mechanism (Screw Terminals, Euro Plug, or Terminal Box protection).

Types of Terminations

Our ceramic band heaters come with multiple termination options, ensuring adaptability for various setups:

- General-Purpose Terminal Boxes for versatile applications.

- Spring-Loaded Clamping Variations for a secure and reliable fit.

- Screw Terminals for straightforward installation.

- Ceramic Band Heaters with Inside SS Cover for enhanced protection and efficiency.

Experience Superior Performance

Choose Alfa Heaters for innovative and dependable heating solutions. Our ceramic band heaters are designed to meet your specific needs, combining energy efficiency, durability, and seamless adaptability. Whether for industrial applications or specialized setups, Alfa Heaters ensures precision and performance every step of the way.

Contact us today to find the perfect solution for your heating requirements!

Connect with us

FAQs - Ceramic Band Heaters

These heaters can operate up to 760°C, suitable for high-temperature industrial processes.

Yes. With built-in insulation and efficient heat transfer, they offer significant energy savings.

Absolutely. They're ideal for barrels, pipes, dies, and other cylindrical equipment.

Up to 7 watts/cm², offering high heating capability in a compact design.

Yes. We offer customizable terminations, including plug types, screw terminals, and armored leads.

Yes, both options are available to suit different mounting needs and installation space.

Yes. Thanks to the flexible ceramic mat and versatile clamping options, installation is quick and secure.

Yes. Thermocouples can be built into the heater based on your process control requirements.

Plastic processing, extrusion, blow molding, cable manufacturing, and heat treatment industries.

Yes. We can provide ceramic band heaters with external blowers for enhanced cooling and air circulation.